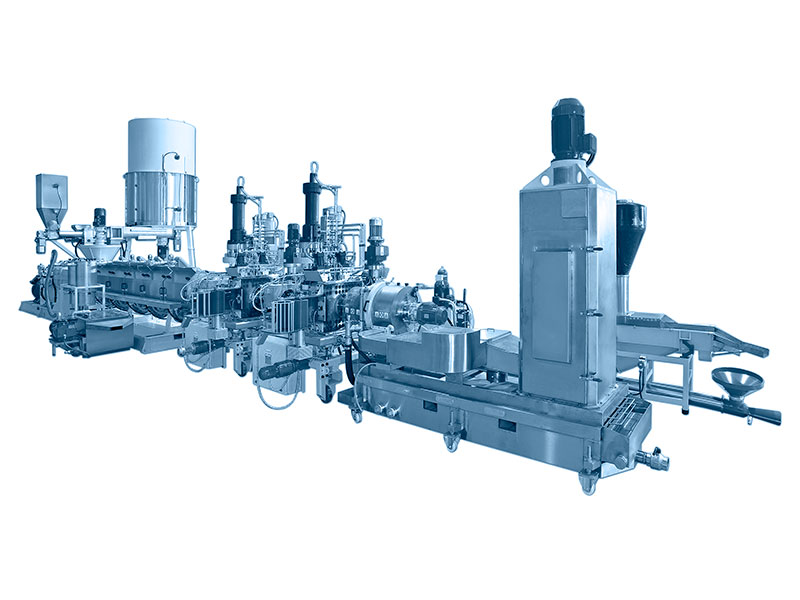

Recycling and compound.

Production lines able to process, in one single step, what typically takes two steps: recycling and compound.

This technology is able to process the post-consumer material in the form of ground sheet and others, coming from a washing plants or not. The pellet obtained guarantees a high quality final product.

The importance of the equipment:

environment and technology

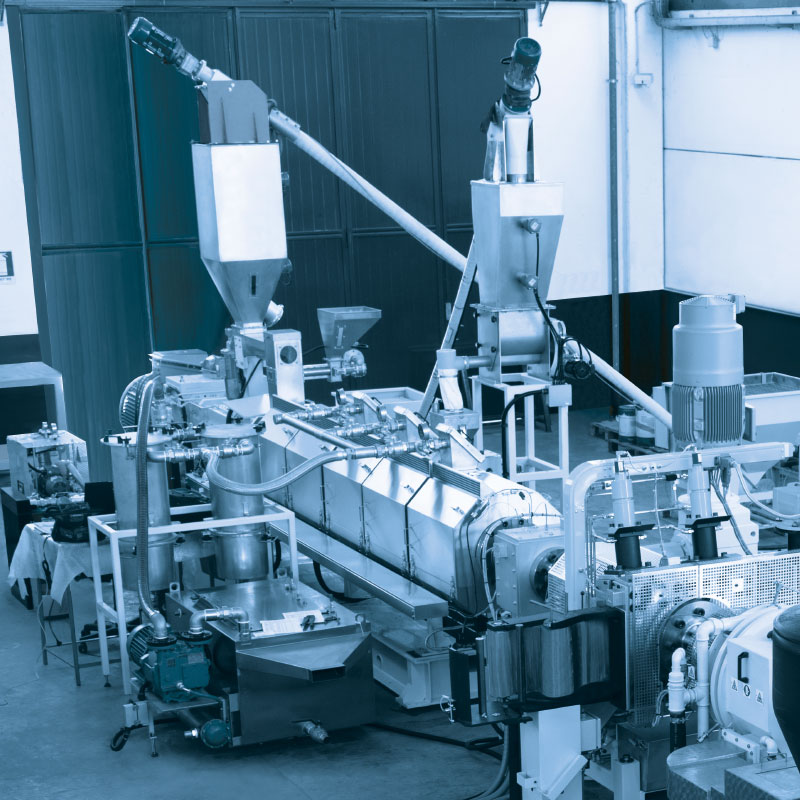

By means of co-rotating twin-screw extruders

the plants are able to compound post-industrial waste with high residual moisture. The presence of a high-vacuum degassing system, distributed over almost the entire length of the extruder barrel, allows the granulation of highly printed films; up to 80% of printed area. The mixing of the raw materials, which occurs directly in the machine, leads to a perfectly homogeneous material able to increase the quality of the final product.

The dosing system of the various materials can be both gravimetric or volumetric. A new gravimetric control system for ground film, although with a bulk density

of around 0.05 kg/dm³, has been patented and developed by the research and development department of Binova: this ensures the exact percentage of ground sheet will feed the extruder.

The concept of this technology is entirely Made in Italy, with particular attention to the quality of

all the components.

Competitiveness in a single step

Being able to carry out this process in one single step makes the line very competitive. We offer our Customers something unique. In addition to the reduced handling of the materials inside the factory, another very important aspect is the proven reduction in energy consumption compared to other plants available on the market today. Compared to a traditional line with a single-screw, the co-rotating twin-screw is able to guarantee up to 30% of energy saving.