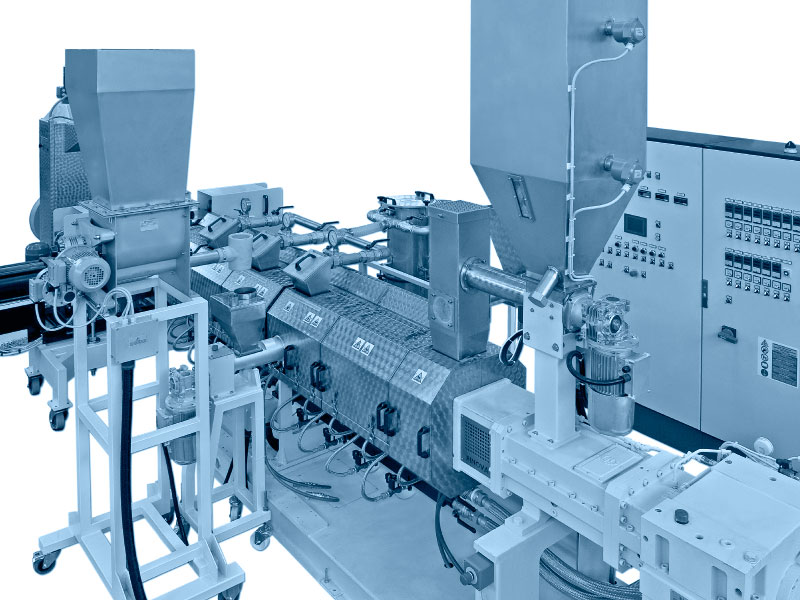

Co-rotating twin-screw

The co-rotating twin-screw extruders use modular barrels and functional extrusion screws, with self-cleaning sectors, installed on grooved shafts. The sector barrels, with different L/D ratios depending on the production process, can be thermostated by water, oil or air, and are manufactured using special chrome steel or, alternatively, bimetallic steel with wear-resistant and/or corrosion resistant additions. In some cases they can be fitted with special internal removable and interchangeable bushings, made of core-tempered

steel with high resistance to wear.

Thanks to the principle of modularity, the twin-screw extruders can be configured to optimize their use according to the intended application.

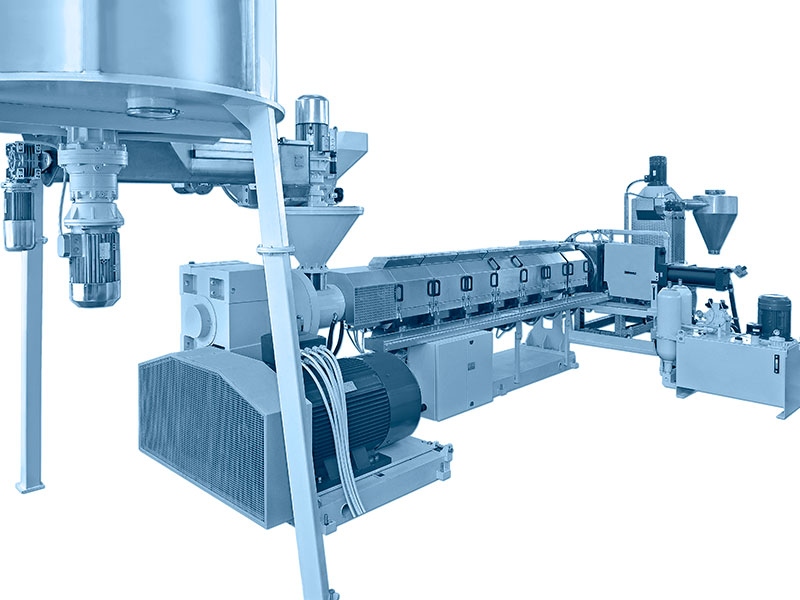

Single-screw

Single-screw extruders use one-piece extrusion screws made of chrome steel with nitriding heat treatment, as well as screws with the addition of a wear-resistant and/or corrosion-resistant alloy, depending on the plastic materials processed. The extrusion barrels, built in two pieces, have different L/D ratios depending on the intended production process, and can be thermostated by air, using electric fans, or by water/oil using a special thermostating unit. The basic materials for barrels manufacture, are special chrome steels, with nitriding heat treatment, or bimetal steels with the addition of a wear-resistant and/or corrosion-resistant alloy up to 2.5 mm thickness.